Root cause failure analysis works by using many different assessments to ascertain the true supply of an item failure. These checks are divided into two groups: non-damaging assessments, which preserve a product intact; and harmful checks, which require the products for being altered so as to examine cross-sections or thermal actions.

The very first respond to then kinds The premise for another “why” question. We hold asking this until we reach some thing elementary or fully beyond our Handle.

Using this, you should not just explore the surface area of deficiencies and errors. You even have to know about the implications in the things that let these failures to materialize. You may additionally consider organizational analysis illustrations.

This emphasis on avoidance might minimize chance of damage to both equally people and team. FMEA is especially practical in analyzing a new process prior to implementation and in examining the effects of the proposed transform to an present method.

Failure analysis of engineering components, structures or methods dependant on materials characterisation approaches and numerical simulations.

The failure analysis process depends on collecting unsuccessful components for subsequent evaluation of the bring about or leads to of failure employing a wide array of procedures, Particularly microscopy and spectroscopy. Nondestructive screening (NDT) methods (for example industrial computed tomography scanning) are valuable since the unsuccessful products are unaffected by analysis, so inspection from time to time begins working with these methods.

Employing this kind of strictly managed and documented system eliminates subjectivity and external affect from product investigations and testing. It offers a scientific and systematic strategy for making use of corrective actions and making quality into current solutions.

Fault tree analysis, failure analysis, and other kinds of analysis files utilized by corporations are vital because they can offer a radical clarification As well as in-depth look at of the small print that businesses really should look into to deal with selected worries or produce certain functions.

It provides whoever developed the solution with info which can help determine how to deal with the situation. The analysis also helps determine what to do to avoid future failures.

Failure mode: Among the ways that an item can fail; considered one of its feasible deficiencies or defects

Our laboratories can speedily deploy a response staff for the failure web site for First documentation and knowledge accumulating and evidence preservation. The important factors are then transported to one of our world-wide laboratories For extra screening germane into the failure investigation.

Failure could be high-priced, regardless of whether resulting from expensive outages, a stopping of generation, or perhaps authorized motion Subsequently. Undertaking failure analysis can avoid these problems from escalating or possible failures from occurring Down the road.

Failure Modes and Effects Analysis (FMEA) is a scientific, proactive method for evaluating a approach to identify in which and how it might fall short and also to evaluate the relative effects of various check here failures, in order to detect the aspects of the method which might be most in need of adjust. FMEA incorporates review of the next:

NTS’ root result in failure tests for metals may help your organization ascertain why metal parts are failing and the way to repair The difficulty. We offer metal screening for shoppers in a wide variety of industries, together with:

Spencer Elden Then & Now!

Spencer Elden Then & Now! Romeo Miller Then & Now!

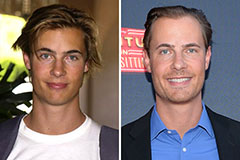

Romeo Miller Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!